Compressed air distribution benefits

Choosing the innovative modular piping by Teseo means adopting the best technology on the market, achieving excellent performance and eliminating the typical hidden costs of managing a compressed air distribution system

Long Lasting

Aluminium does not rust and is not subject to corrosion, thus inside a TESEO pipe the air is clean as soon as treated at the origin. This ensures longer life of all the devices connected to it.

Profiles and accessories are made of sturdy 100% recyclable aluminium, all pipes and fittings are in fact 100% metal, safe and reliable.

Excellent performance

“It’s like having an extra compressor!”. This is the comment that different customers have given us after moving to a TESEO system.

The superb design of TESEO pipes joined to the reliability and the lightweight of aluminium, are maximizing the performance of each operational phase of the project, both in a factory, on board of a machine or feeding an air tool.

Cost reductions

There are many typical hidden costs when running a compressed air distribution system. TESEO eliminates these costs, constantly rising during the entire life of the plant distribution.

Let's see some:

- Costs for air leaks.

- Costs for air treatment, maintenance and repair of machines and tools.

- Costs for downtime and labor-costs for each modification.

- Costs due to low flow rates and high pressure drops.

Energy Saving

The high-precision extruded profiles by TESEO have a smooth inner surface and that is why the friction of the air flowing through the pipe is considerably lower compared to a conventional black or galvanized steel pipe. This precisely leads to a lower pressure drop and a higher flow rate with equal consumption of electricity.

In addition, the patented locking system and sealing of our piping system eliminates a huge problem, guarantees savings in a lot of normally wasted energy.

Reduced times

Time reduction and downtime elimination are critical to manufacturing and productive processes.

A Teseo distribution system is easy to modify and extend, like a simple energy manifold inside the factory. Each element is designed to be lightweight, flexible and modular, so that adding a new machine or a new point of use will require a few minutes to get started.

High efficiency

You can explain in many different ways the extraordinary efficiency of TESEO products; from the smoothness of the internal bore, to the optimized thickness to increase the flow, from the double seats for the blue O-rings on all connectors, to the new outlet plates, from the design of shapes and volumes for improving ergonomics to the study of details that increase energy efficiency.

We like to measure it with the satisfaction of our customers.

Contact your closer sales representative for more information.

Contact us now

What Teseo does

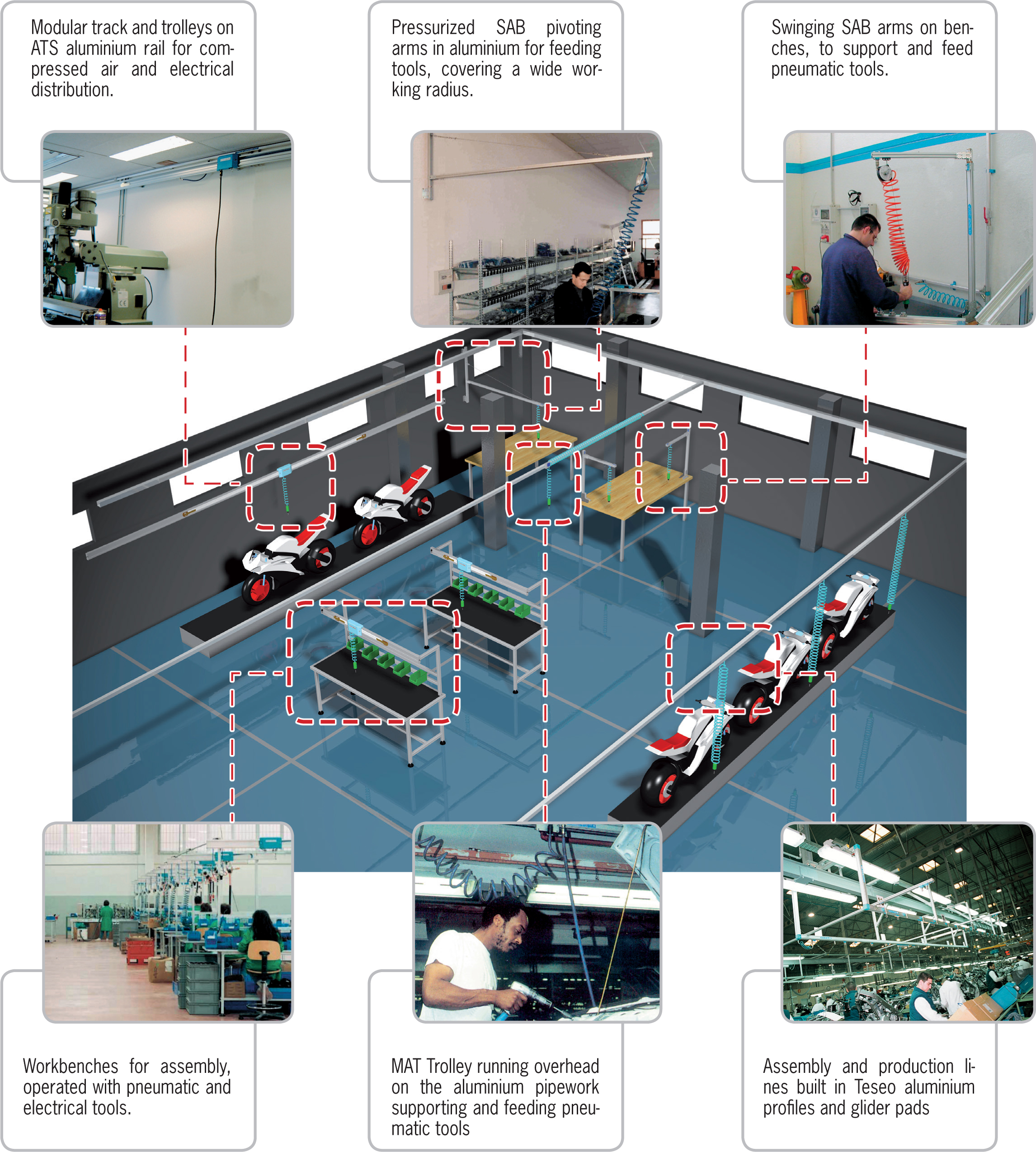

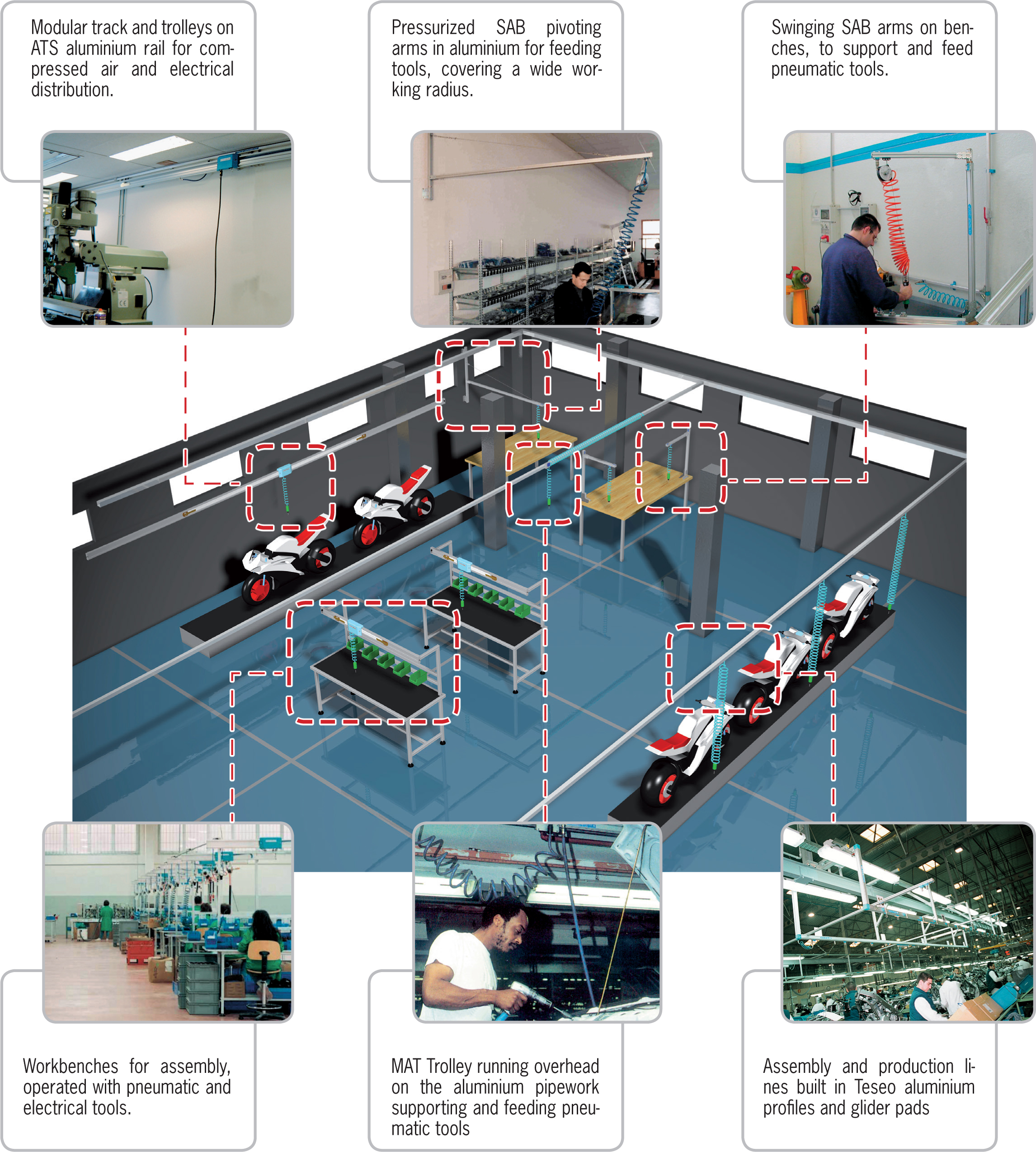

ERGONONIC SOLUTIONS FOR PNEUMATIC TOOLS

- Modular track and trolleys on ATS aluminium rail for compressed air and electrical distribution.

- Pressurized SAB pivoting arms in aluminium for feeding tools, covering a wide working radius.

- Swinging SAB arms on benches, to support and feed pneumatic tools.

- Workbenches for assembly, operated with pneumatic and electrical tools.

- MAT Trolley running overhead on the aluminium pipework supporting and feeding pneumatic tools

- Assembly and production lines built in Teseo aluminium profiles and glider pads

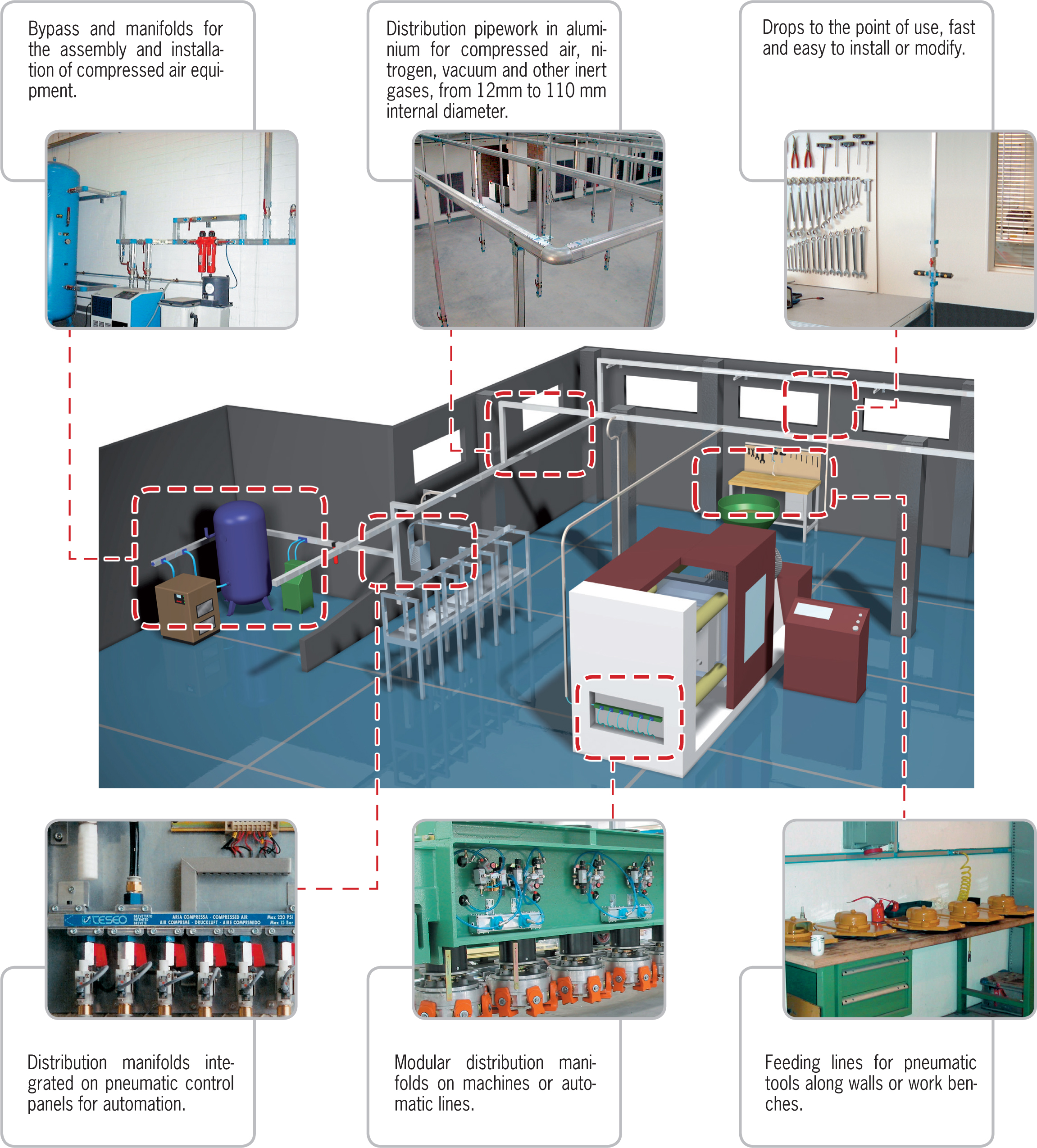

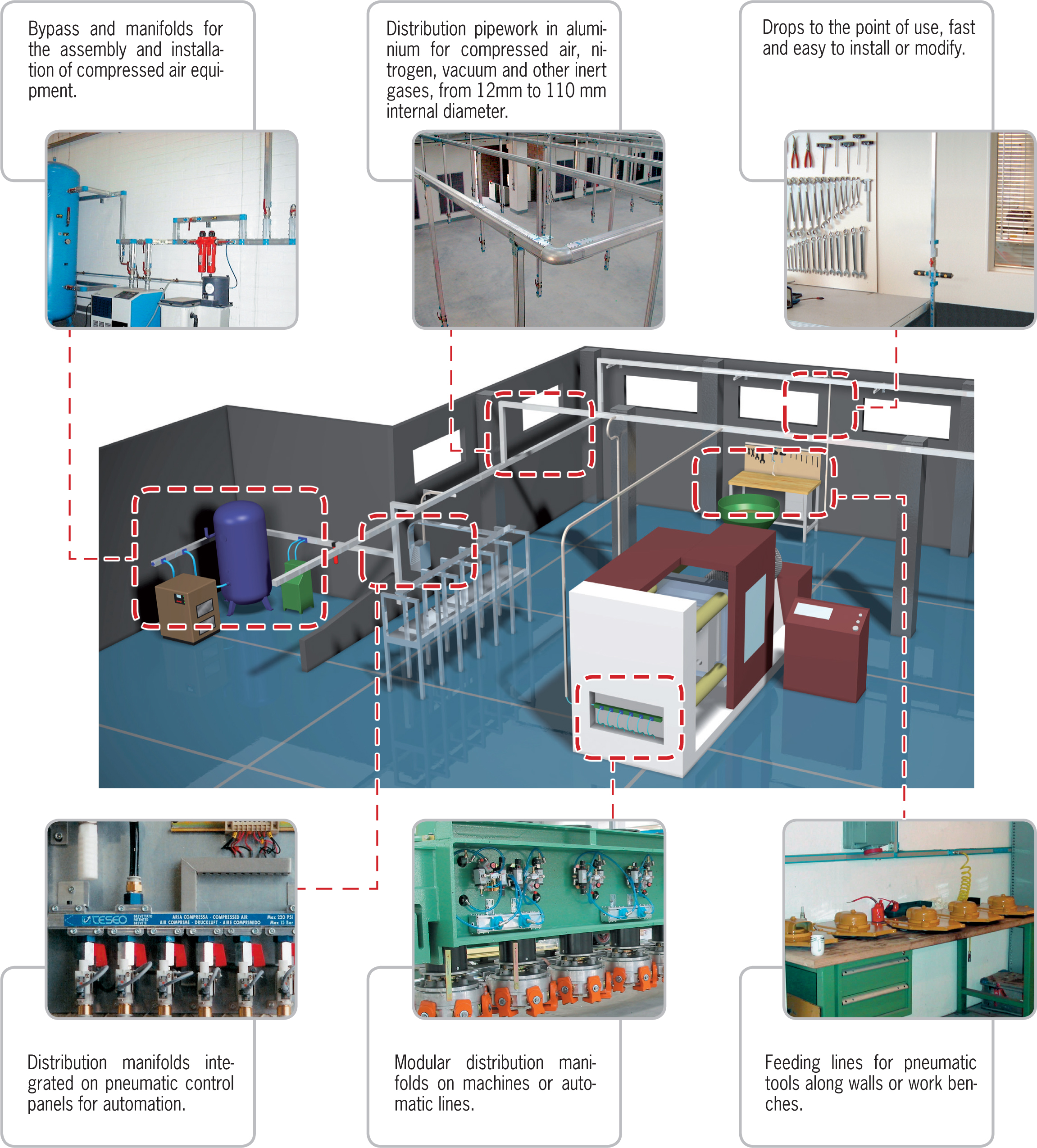

FLUID POWER IN THE FACTORY AND ON MACHINERY

- Bypass and manifolds for the assembly and installation of compressed air equipment.

- Distribution pipework in aluminium for compressed air, nitrogen, vacuum and other inert gases, from 12mm to 110 mm internal diameter.

- Drops to the point of use, fast and easy to install or modify.

- Distribution manifolds integrated on pneumatic control panels for automation.

- Modular distribution manifolds on machines or automatic lines.

- Feeding lines for pneumatic tools along walls or work benches.

Contact our technical office for a quick check-up of your system.

We will provide you with an analysis of compressed air costing and potential savings

Contact us now